Industry overview

Industry vs. energy transition & consumption– our motto: Do the feasible now

A rapidly completed energy turnaround, with a stable energy supply and affordable kilowatt hours, is the challenge of our current decade.

Yes, it is a challenge for all of us … but first and foremost also an opportunity for society and industry.

It is precisely in order to efficiently and sustainably meet the ever-growing energy demands of modern industrial networks that our customers use the low-loss, high-performance, intelligent filter circuit and compensation solutions from Condensator Dominit GmbH.

We help you to do what is feasible… because we don’t just do it, we listen to you, analyse exactly. Then we reach into our voltage-optimizing power quality toolbox and deliver the best possible solution for you, both technically and economically.

Switchgear manufacturers - Electrical contractors - Plant planning service providers

Electrical contractors, switchgear manufacturers and plant planning service providers make up an important and large proportion of our very diversified clientele worldwide. Typical characteristics of these ‘Our partners in works and spirit’ are: exceptional specialist knowledge of energy or electrical engineering, rich in professional experience and always possess – through planning processes carried out by them – deep knowledge of the existing or soon to be developed energy network. Knowledge of network peculiarities, connected loads, lines and transformers, the respective contactors and main distributions … for planners, the master craftsman’s company and skilled workers no problem at first. However, even in the networks of our partners’ customers, norm-breaking and destabilising network reactions must be taken into account and filtered if necessary, even in the preliminary project phase by the electrical planner or in the continuous energy network support by electrical specialist companies or switchgear manufacturers. Every target group receives the necessary support from us in the area of power quality, in order to stand on a safe footing from the planning phase to the project planning phase to the continuous support phase of electrical power networks and the loads connected to them. Our partners benefit from the creation of DIgSILENT network simulations, voltage analyses including measurement reports, our competent engineering and after-sales service team as well as a thoroughly structured, standardised power quality product portfolio. This includes the modular GridClass®Mod product range, which was specially developed for switchgear manufacturers and electrical contractors. We supply – neutrally – the mains filter or compensation module and the installation or further added value remains with the switchgear manufacturer.

Renewable energies (Wind-Solar-H2)

The mix of renewable energy producers such as wind power, solar and hydrogen electrolysis will make us less dependent on fossil fuels in the coming years. However, renewable energy sources must not simply feed into the existing European interconnected grid. Why? Imagine two pianos on which two pianists want to play a duet together. Before the performance, the two instruments must also be tuned to each other – by a specialist – according to certain rules, so that a good-sounding duet is possible at all. The specialists from Condensator Dominit are your “piano tuners” for wind, solar or hydrogen electrolysis parks, in order to enable a standard-compliant feed-in of regenerative energies.

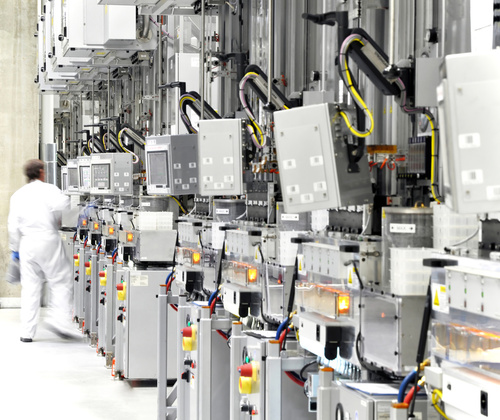

Automotive industry

The power networks in the automotive industry are subject to high harmonic loads due to the many different loads such as robots, PCs, frequency converter-controlled pumps, ventilation systems, CNC processing machines, conveyor belts, cranes, electrical lifting equipment and the many other non-linear loads. These harmonics lead to a distortion of the 50 Hz AC sine wave, which causes problems at the equipment connected in the automotive plant. The effects range from malfunctions to the destruction of systems, equipment and safety devices due to overvoltages. Our patented SOFIA® filter circuit system provides a remedy here. In 2015, we did not simply develop it for an automobile manufacturer, but the systems have started a real triumphal procession through the worldwide automobile productions of all manufacturers.

Metal- & Steel industry

Pharma- & Chemical industry

Food- & nutrition industry

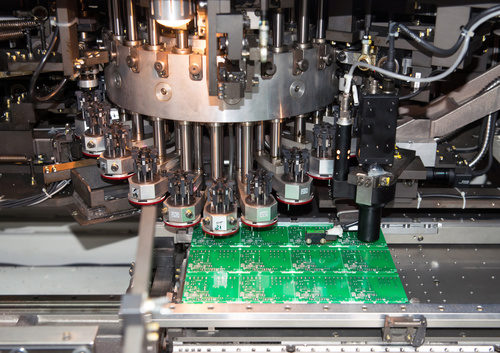

Semiconductor industry

Coal, steel & building materials industry

Wood & paper industry

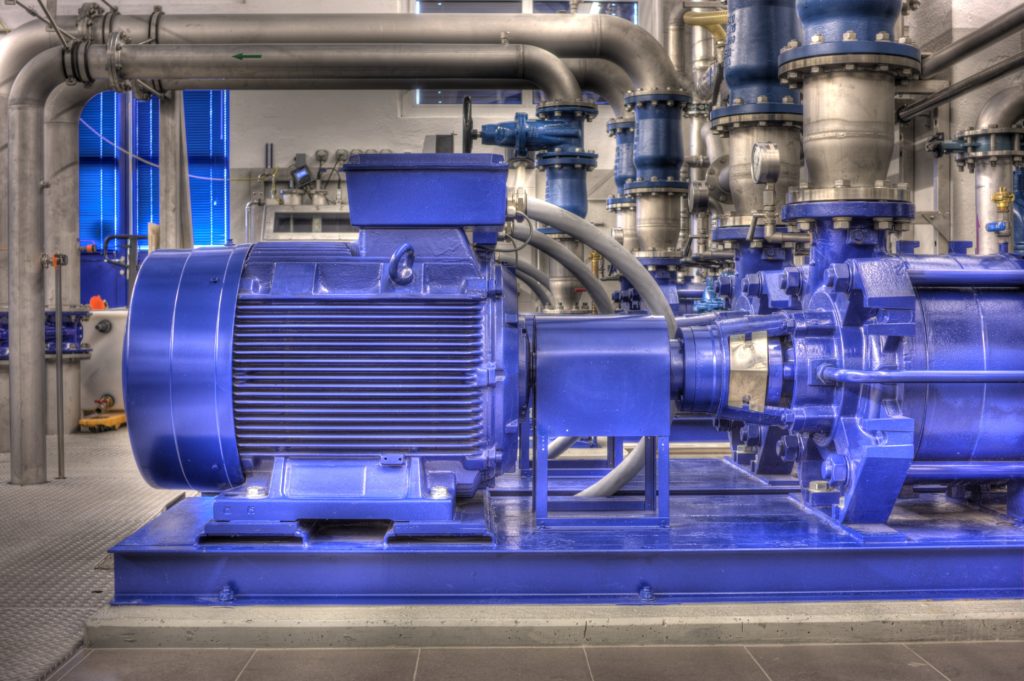

Water supply & disposal companies

Ship & yacht building industry